Thermoforming Moulds

Thermoforming Moulds

3 Station Moulds

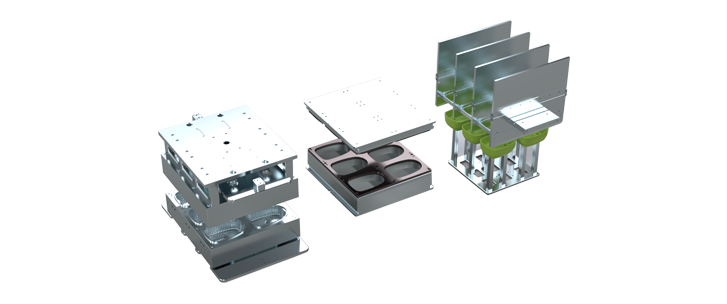

3 Station Thermoforming Moulds

Doganay Mould specializes in advanced 3-station thermoforming molds, meticulously designed to streamline the production process and ensure consistent quality. A 3-station thermoforming mold (or tooling) includes three essential sections: forming, cutting, and stacking. Each station is optimized to work seamlessly with the next, enhancing efficiency and accuracy at every stage of the production line.

The first station, forming, is where the thermoforming tooling shapes the material into the desired form through heat and pressure. This crucial step ensures each tooling process creates a durable, precise product. Moving to the second station, cutting, the mold is engineered to trim the formed material accurately, meeting high standards for precision and waste reduction. Finally, the stacking station organizes the finished products, carefully stacking them for efficient handling and packaging.

Doganay Mould’s 3-station thermoforming tooling is crafted to meet rigorous industry standards, ensuring reliability and longevity. With our advanced tooling capabilities, we guarantee each thermoforming mold is built to deliver repeatable quality, making it ideal for high-volume production environments. Our commitment to quality and efficiency in every moulding process sets us apart, ensuring clients can rely on our thermoforming tooling for seamless production workflows.

Doganay Mould continues to innovate in the thermoforming mold sector, offering tooling solutions that embody precision, durability, and efficiency. Each thermoforming mould in our 3-station lineup is crafted to offer robust performance and enhance productivity, making Doganay Mould the trusted partner for high-quality thermoforming tooling solutions.

View Detail

3 Station Moulds

3 Station Thermoforming Moulds

Doganay Mould specializes in advanced 3-station thermoforming molds, meticulously designed to streamline the production process and ensure consistent quality. A 3-station thermoforming mold (or tooling) includes three essential sections: forming, cutting, and stacking. Each station is optimized to work seamlessly with the next, enhancing efficiency and accuracy at every stage of the production line.

The first station, forming, is where the thermoforming tooling shapes the material into the desired form through heat and pressure. This crucial step ensures each tooling process creates a durable, precise product. Moving to the second station, cutting, the mold is engineered to trim the formed material accurately, meeting high standards for precision and waste reduction. Finally, the stacking station organizes the finished products, carefully stacking them for efficient handling and packaging.

Doganay Mould’s 3-station thermoforming tooling is crafted to meet rigorous industry standards, ensuring reliability and longevity. With our advanced tooling capabilities, we guarantee each thermoforming mold is built to deliver repeatable quality, making it ideal for high-volume production environments. Our commitment to quality and efficiency in every moulding process sets us apart, ensuring clients can rely on our thermoforming tooling for seamless production workflows.

Doganay Mould continues to innovate in the thermoforming mold sector, offering tooling solutions that embody precision, durability, and efficiency. Each thermoforming mould in our 3-station lineup is crafted to offer robust performance and enhance productivity, making Doganay Mould the trusted partner for high-quality thermoforming tooling solutions.

View Detail

4-Station Moulds

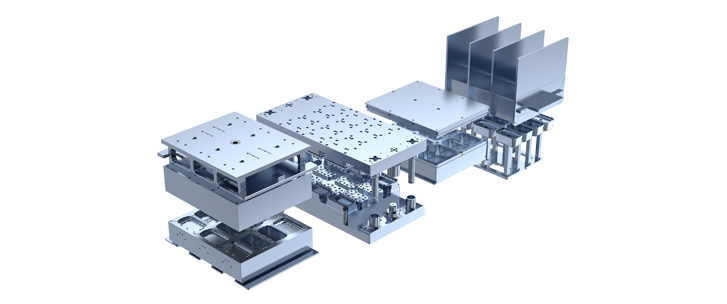

4 Station Thermoforming Moulds

Doganay Mould’s 4-station thermoforming molds are designed to meet the most intricate production needs, incorporating a specialized punching station that occurs between the first forming and second cutting stages. This punching station is essential when products require precision-drilled holes, making it an integral part of our advanced thermoforming tooling. The tooling precision in this station is of the utmost importance, as it ensures holes are cut cleanly and burr-free—a requirement for high-quality end products.

The materials used for the punching steels in our thermoforming molds are carefully selected to withstand high-frequency use while maintaining sharpness and durability. The quality of these materials directly impacts the tooling's accuracy, ensuring each thermoforming mould performs at peak efficiency. With Doganay Mould’s expertise, we create punching stations that guarantee flawless cuts, contributing to an overall mold design that is both efficient and durable.

At Doganay Mould, we understand the impact that superior thermoforming tooling has on production quality. Our 4 station molds, featuring this precise punching capability, are crafted to provide maximum precision and longevity, setting a high standard in the industry. Each thermoforming mold is meticulously inspected to ensure it meets rigorous quality standards, providing reliable and consistent results with every use.

Choose Doganay Mould’s 4-station thermoforming tooling for a complete, high-quality solution. Our advanced punching station, along with our commitment to exceptional mold quality, ensures that our thermoforming molds consistently exceed client expectations.

View Detail

4-Station Moulds

4 Station Thermoforming Moulds

Doganay Mould’s 4-station thermoforming molds are designed to meet the most intricate production needs, incorporating a specialized punching station that occurs between the first forming and second cutting stages. This punching station is essential when products require precision-drilled holes, making it an integral part of our advanced thermoforming tooling. The tooling precision in this station is of the utmost importance, as it ensures holes are cut cleanly and burr-free—a requirement for high-quality end products.

The materials used for the punching steels in our thermoforming molds are carefully selected to withstand high-frequency use while maintaining sharpness and durability. The quality of these materials directly impacts the tooling's accuracy, ensuring each thermoforming mould performs at peak efficiency. With Doganay Mould’s expertise, we create punching stations that guarantee flawless cuts, contributing to an overall mold design that is both efficient and durable.

At Doganay Mould, we understand the impact that superior thermoforming tooling has on production quality. Our 4 station molds, featuring this precise punching capability, are crafted to provide maximum precision and longevity, setting a high standard in the industry. Each thermoforming mold is meticulously inspected to ensure it meets rigorous quality standards, providing reliable and consistent results with every use.

Choose Doganay Mould’s 4-station thermoforming tooling for a complete, high-quality solution. Our advanced punching station, along with our commitment to exceptional mold quality, ensures that our thermoforming molds consistently exceed client expectations.

View Detail

IMC

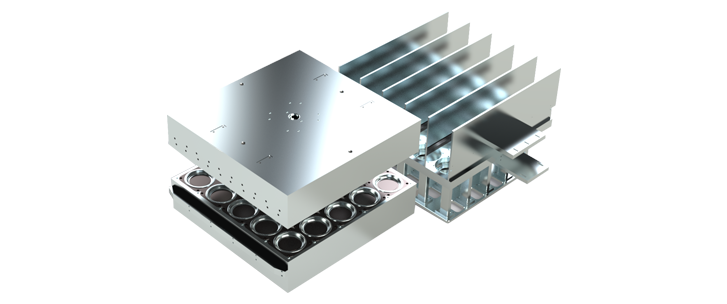

IMC Thermoforming Moulds

Doganay Mould offers innovative solutions in the industry with IMC thermoforming molds, where the forming and cutting processes are performed in the same station. This type of mold allows for simultaneous shaping and cutting, enhancing efficiency in the production process. The IMC thermoforming tooling includes stacking as the second station, providing a significant advantage in achieving better cutting alignment.

The primary benefit of IMC thermoforming molds is the improved precision in cutting alignment, ensuring that cuts are made accurately and consistently. This precision is crucial for maintaining high-quality standards in production. Each thermoforming mould designed with IMC technology is engineered to ensure that the cutting process is perfectly centered, minimizing errors during production.

At Doganay Mould, we focus on delivering superior thermoforming tooling solutions that prioritize accuracy. Our IMC designs emphasize the importance of cutting alignment, ensuring that each thermoforming mold meets stringent quality criteria. The integration of moulding and cutting processes not only enhances production speed but also contributes to overall efficiency.

Choose Doganay Mould’s IMC thermoforming tooling for a solution that excels in cutting alignment and quality. We are committed to providing the best outcomes for our clients through continuous innovation and superior design.

View Detail

IMC

IMC Thermoforming Moulds

Doganay Mould offers innovative solutions in the industry with IMC thermoforming molds, where the forming and cutting processes are performed in the same station. This type of mold allows for simultaneous shaping and cutting, enhancing efficiency in the production process. The IMC thermoforming tooling includes stacking as the second station, providing a significant advantage in achieving better cutting alignment.

The primary benefit of IMC thermoforming molds is the improved precision in cutting alignment, ensuring that cuts are made accurately and consistently. This precision is crucial for maintaining high-quality standards in production. Each thermoforming mould designed with IMC technology is engineered to ensure that the cutting process is perfectly centered, minimizing errors during production.

At Doganay Mould, we focus on delivering superior thermoforming tooling solutions that prioritize accuracy. Our IMC designs emphasize the importance of cutting alignment, ensuring that each thermoforming mold meets stringent quality criteria. The integration of moulding and cutting processes not only enhances production speed but also contributes to overall efficiency.

Choose Doganay Mould’s IMC thermoforming tooling for a solution that excels in cutting alignment and quality. We are committed to providing the best outcomes for our clients through continuous innovation and superior design.

View Detail

Thermoforming Mould

Doganay Mould specializes in the production of high-quality thermoforming moulds, catering to the unique needs of various industries. Our company prides itself on a team of skilled engineers and experienced specialists, all dedicated to precision and excellence. Each thermoforming mold is crafted with attention to detail and commitment to quality, ensuring a robust and efficient production process.

Our extensive range of machinery enables us to handle even the most complex tooling requirements. By utilizing advanced equipment and innovative technology, we strive to maintain our position as a reliable partner in the thermoforming mold industry. At Doganay Mould, we recognize the importance of investing in the latest machinery and techniques to ensure our clients receive durable and efficient thermoforming tooling solutions.

Whether you need a custom-made mold or a more standard thermoforming mould, our team is equipped to deliver solutions that meet your specific requirements. Through rigorous testing and quality control, we make sure every mold we produce aligns with industry standards and client expectations.

Our commitment to excellence, combined with our comprehensive machine park and dedicated team, makes Doganay Mould a leader in thermoforming tooling. Choose Doganay Mould for quality, reliability, and a partnership built on trust.